Introduction

In today's complex electronic devices, efficient power management is crucial! Power Management Integrated Circuits (PMICs) play a critical role by efficiently controlling and regulating power across various system components. Understanding PMIC meaning is essential for anyone involved in electronics design or repair.

A PMIC is a specialized chip that controls various aspects of power delivery and consumption within a device. This includes voltage regulation, battery charging, and power sequencing. The significance of PMIC meaning extends to optimizing performance and extending battery life in everything from smartphones and laptops to industrial equipment. Delving deeper into PMIC meaning reveals the intricate functionalities within these essential components, which are critical for the operation of modern electronic systems.

Significance of PMIC

Power Management Integrated Circuits (PMICs) represent a $79 billion market, projected to revolutionize electronic power systems by 2025. [1] Unlike traditional discrete power management solutions that require multiple components for voltage regulation and power sequencing, modern PMICs integrate sophisticated power control functions into single-chip solutions. These circuits optimize power efficiency, reduce power consumption, and enhance battery life, making them essential for next-generation electronic devices across multiple industries.

Power Management Integrated Circuit (PMIC)

These advanced circuits demonstrate remarkable versatility across multiple sectors:

- Wearables: nPM2100 PMIC by Nordic enables advanced battery management with 315mA charging capabilities, supporting low-dropout (LDO) regulators and DC-DC conversion for maximum energy efficiency in compact smartphones, IoT, and medical devices.

- Automotive: OPTIREG series by Infineon delivers ASIL-D compliant power solutions, integrating DC converters, MOSFETs, and linear regulators to ensure stable power supply for automotive electronics, microcontrollers, and safety-critical systems.

- Energy Harvesting Systems: NEH71x0 PMIC by Nexperia achieves 95% conversion efficiency with its innovative inductor-less design. [2] This enables power conversion from low-voltage sources, such as solar panels and thermal energy systems, for use in IoT devices, real-time monitoring systems, and remote sensors.

This level of integration and efficiency has become crucial for the exponential growth of IoT devices and edge computing systems, where power optimization directly impacts device autonomy and performance. PMICs serve as the cornerstone of modern system design, enabling the development of increasingly sophisticated and energy-efficient systems.

PMIC Fundamentals

Core Functions in Electronic Systems

PMICs represent a fundamental shift in how electronic systems handle power distribution, power control, and regulation. They integrate sophisticated power control functions into single-chip solutions, enabling precise power delivery across multiple voltage domains in semiconductor, IoT, industrial, and consumer electronics applications.

Let’s go through this feature comparison of Traditional Power Management vs. PMICs:

| Feature | Traditional Power Management | PMIC |

| Component Count | High (Multiple Components) | Low (Single Chip) |

| Integration Level | Low (Discrete Components) | High (Multi-Function Integration) |

| Efficiency | Moderate | High |

| Scalability | Limited | Flexible |

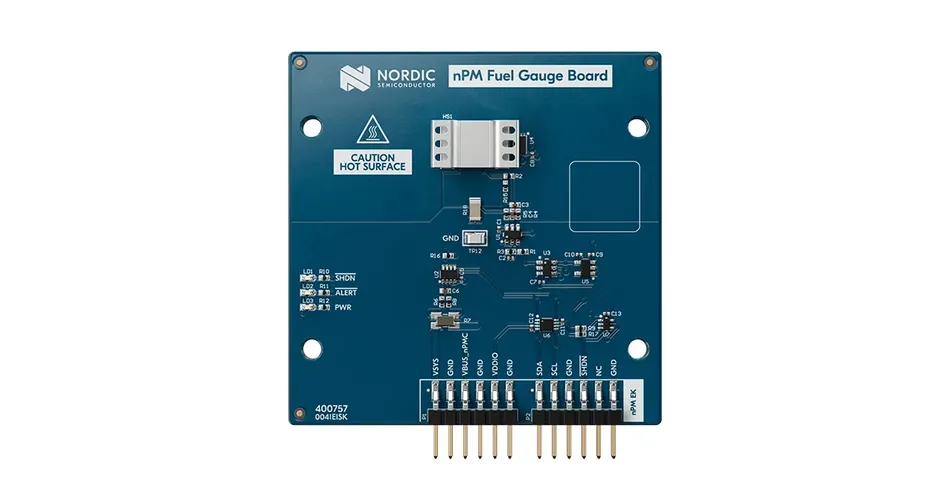

Modern PMICs employ dynamic voltage scaling techniques, as seen in Fuel Gauge technology by Nordic, which optimizes power consumption through real-time battery monitoring. This technology accurately estimates battery charge levels from 0 to 100% while maintaining ultra-low power consumption.

nPM Fuel Gauge board; Source: Nordic Semiconductor

Key power management capabilities include:

1. Dynamic Voltage/Frequency Scaling (DVFS):

- Adjusts voltage and frequency based on system demands, reducing power consumption while maintaining performance.

- Example: The architecture of TRAVEO T2G by Infineon, supports voltage domains from 2.7V to 5.5V for automotive microcontrollers.

2. Battery Management:

- Implements advanced charging algorithms, low-dropout (LDO) regulators, and smart sleep modes to optimize battery life.

- Example: 315mA charging capability by Nordic with optimized power sequencing for battery-powered devices.

3. Power Sequencing:

- Coordinates multiple power rails with precise timing, ensuring proper system initialization and shutdown sequences.

- Example: Dedicated standby mode controllers manage power sequencing in high-performance computing and automotive electronics.

By integrating these advanced power control mechanisms, PMICs significantly improve power efficiency, thermal management, and scalability. This makes them essential for next-generation microcontrollers, processors, and electronic systems.

Key Components and Architecture

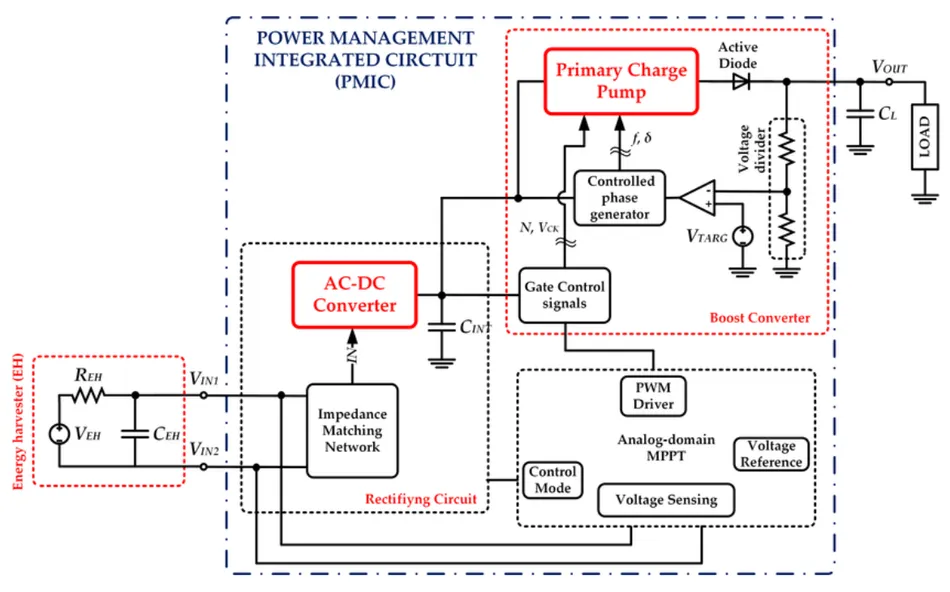

The fundamental architecture of modern PMICs centres around sophisticated power conversion and regulation systems.

PMIC Architecture; Source: Research Gate

Buck/Boost Converters form the core of voltage conversion, enabling both step-up and step-down operations with efficiency ratings exceeding 95%. These converters operate through high-frequency switching mechanisms, typically operating in the 2MHz range for optimal performance.

- Step-Down Conversion (Buck Regulator): Reduces high-voltage inputs to lower levels suitable for microprocessors, FPGAs, and embedded systems.

- Step-Up Conversion (Boost Regulator): Increases low voltage sources, enabling efficient battery-powered applications, such as wearables and IoT devices.

The Renesas SLG51002 exemplifies the evolution in regulator technology, featuring eight customizable low dropout regulators (LDOs) designed for high-performance applications. These LDO regulators ensure:

- Low noise operation, critical for RF and sensor-based applications.

- Faster transient response, maintaining stability under dynamic load conditions.

- Optimized energy efficiency, reducing power dissipation in low-voltage environments.

While switching regulators are more efficient for large voltage differentials, LDOs are preferred for sensitive analog circuits, including audio amplifiers, ADCs, and RF communication systems.

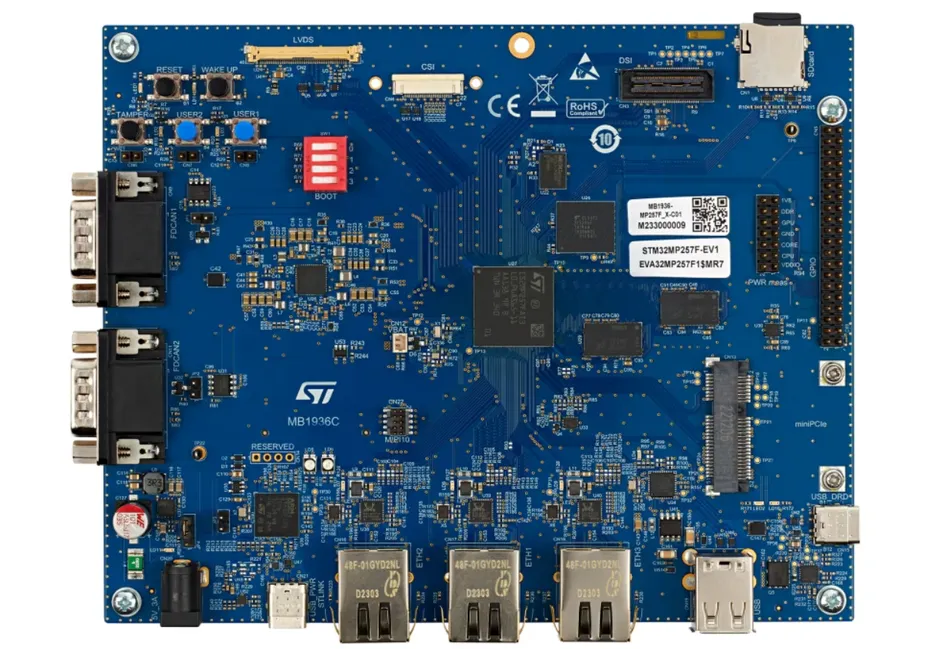

STM32MP257F-EV1 Evaluation Board; Source: ST

Modern PMICs integrate sophisticated monitoring and control mechanisms, such as analog-to-digital conversion (ADC) units, to enhance real-time power management. The STM32MP25xA series incorporates three 12-bit ADCs, each supporting 5 Msps sampling rates, which:

- Enable high-speed data acquisition across 23 channels (single-ended mode) or 11 channels (differential mode).

- Feature built-in voltage reference (VREF) generation, supporting 1.21V, 1.5V, or external reference options for precision power monitoring.

By incorporating high-efficiency power conversion, real-time voltage regulation, and intelligent power sequencing, modern PMICs enable low power consumption, enhanced energy efficiency, and greater scalability in complex electronic systems.

Advanced PMIC Implementations

Energy Harvesting Systems

Modern PMICs have revolutionized energy harvesting capabilities through sophisticated power management techniques and innovative designs. These enhancements enable electronic devices to function independently, drawing energy from ambient sources such as solar, kinetic, and thermal gradients.

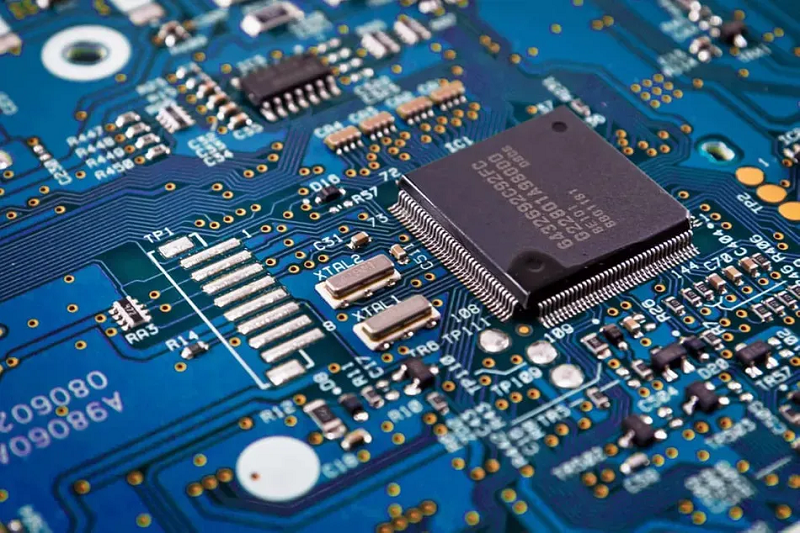

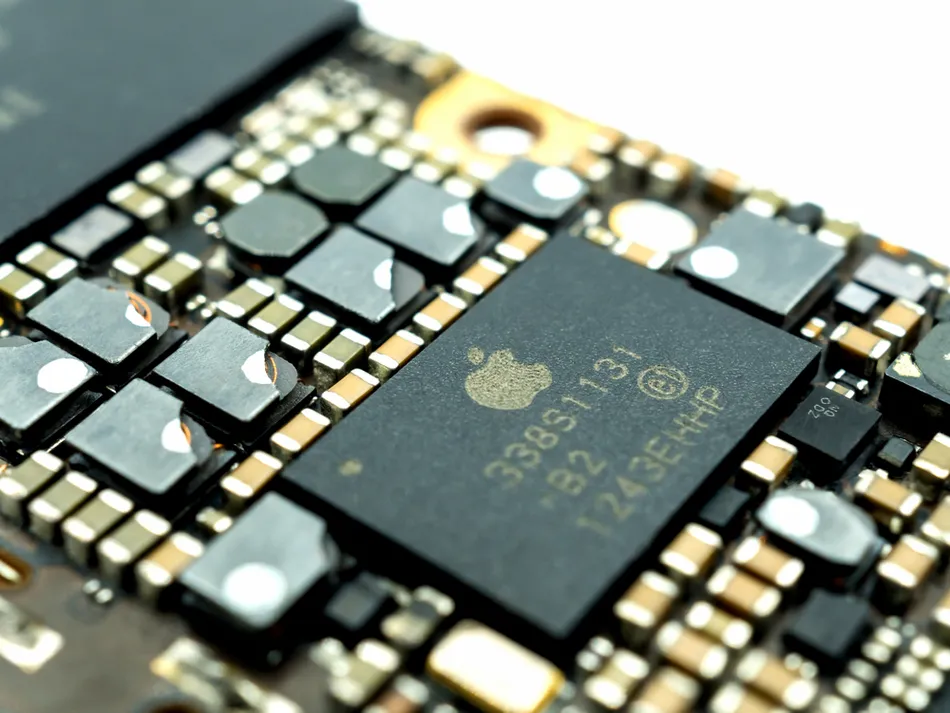

Power Management IC chip on Apple iPhone logic board

Two leading solutions demonstrate distinct approaches to energy efficiency and power management:

| Feature | NEH71x0 | nPM2100 |

| Input Range | 15μW 100mW | 0.7V - 3.4V Primary Cells |

| Efficiency | 95% Conversion | 90.5% at 10μA |

| Key Innovation | Inductor Less Design | Advanced Fuel Gauging |

| Operating Mode | Energy Harvesting | Primary Cell Optimization |

| Package Size | 4x4mm QFN28 | 1.9x1.9mm WLCSP |

| Special Features | Cold Start Capability | Break-to-Wake Function |

Maximum Power Point Tracking (MPPT) algorithm, integrated into NEH71x0 by Nexperia, is a key advancement in energy harvesting PMICs. This feature operates on a 0.5-second adaptation cycle, continuously optimizing power extraction from various ambient energy sources, including:

- Light (Photovoltaic Cells)

- Kinetic Motion (Piezoelectric Generators)

- Thermal Gradients (Thermoelectric Generators - TEGs)

By dynamically adjusting to environmental changes, MPPT ensures the highest possible energy conversion efficiency, maintaining peak system performance in ultra-low-power applications.

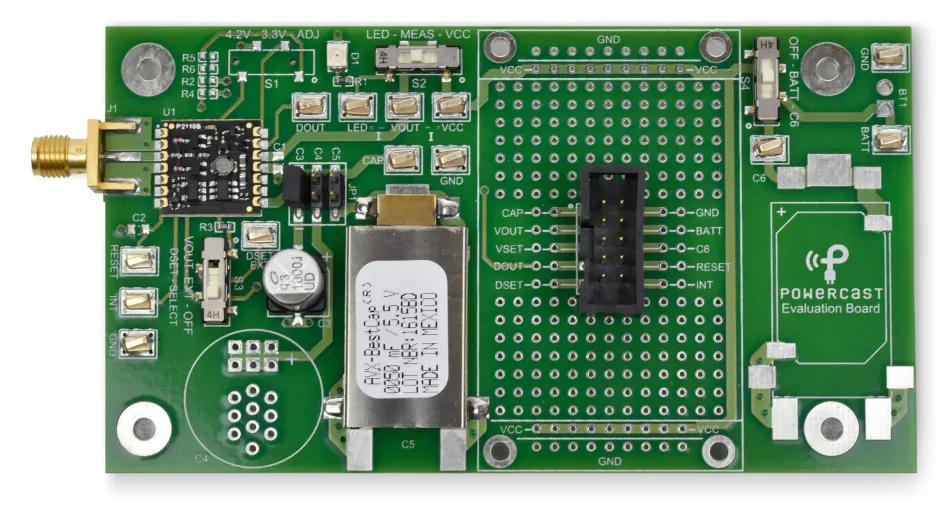

P2110-EVAL-02 Powercast - RF Energy Harvesting Enables Wireless Power in Medical Applications

One of the most groundbreaking features in modern energy harvesting PMICs is their ability to cold start from an extremely low-power state. This capability is crucial for battery-free IoT sensors, industrial automation, and medical implants, where external power sources are unreliable.

- Cold Start from 15μW: The NEH71x0 can initialize operation from a completely discharged state, utilizing only 15μW of ambient energy to bootstrap its core functions.

- Progressive Energy Build-Up: The system efficiently harvests energy and stores it for future use while maintaining continuous power conversion.

- Autonomous and Maintenance-Free Operation: This innovation enables IoT and edge computing devices to operate indefinitely without battery replacements, reducing maintenance costs and environmental impact.

By integrating real-time power management, low-voltage operation, and dynamic power conversion, advanced PMICs are paving the way for the next generation of self-sustaining, high-efficiency electronic systems.

Automotive-Grade Power Solutions

PMICs are engineered to meet the rigorous demands of advanced driver assistance systems (ADAS), electric powertrains, and next-generation in-vehicle computing platforms. These high-reliability solutions comply with ISO 26262 functional safety standards, ensuring real-time fault detection, voltage regulation, and multi-domain power sequencing for safety-critical applications.

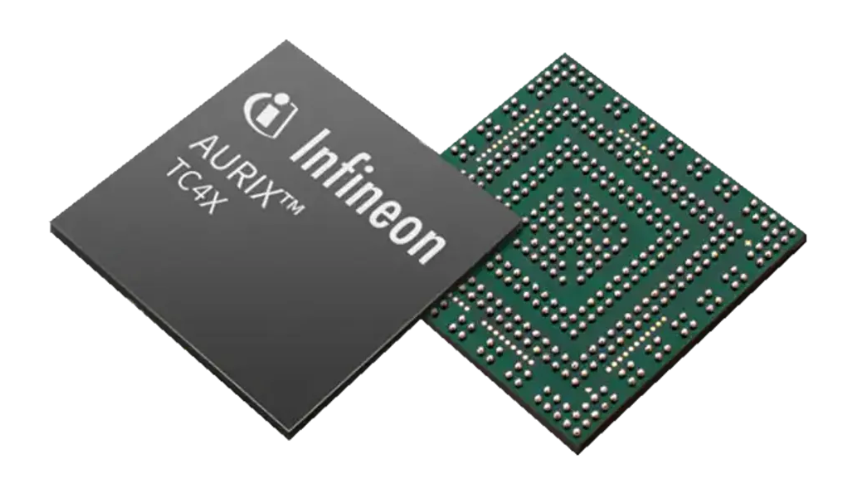

AURIX TC4x 32-bit TriCore Microcontrollers

The TLF4D985QKV03 demonstrates comprehensive ASIL-D compliance, integrating system integrity support and dedicated compute and control features under the AURIX™ Freedom from Interference framework. This architecture ensures:

- Multi-domain power management with strict isolation between safety-critical and non-critical functions.

- On-chip monitoring & power sequencing to maintain stable voltage regulation in high-performance automotive microcontrollers.

- Fail-safe fault response mechanisms, preventing power disruptions in autonomous and semi-autonomous systems.

The NXP FS26 System Basis Chip (SBC) provides a robust power control architecture, tailored for electric vehicles, hybrid powertrains, and ADAS computing systems. Key features include:

- Multiple switch-mode regulators with independent voltage-tracking capabilities for efficient power conversion.

- Real-time latent fault monitoring with on-demand diagnostics to detect voltage drops, overheating, and EMI-related failures.

- ISO 26262 certification supporting both ASIL-B and ASIL-D safety integrity levels, ensuring compliance for mission-critical applications.

- Fail-safe outputs & automated fault response, enhancing electronic stability control (ESC) and active suspension systems.

- Integrated voltage reference system, enabling precise power regulation across multi-rail architectures.

Cockpit & ADAS Integration Platform

Modern automotive PMICs power a wide range of critical subsystems, including 48V mild-hybrid systems, battery management modules, and ADAS computing platforms.

1. 48V Systems:

- Bi-Directional DC-DC Conversion: Enables power transfer between low-voltage (12V) and high-voltage (48V) networks, improving energy efficiency in mild hybrid architectures.

- High-Efficiency Power Delivery: Supports electric superchargers, active suspension, and regenerative braking systems.

- Integrated Load Dump Protection: Prevents voltage spikes from damaging electronic control units (ECUs) and battery management ICs.

2. Battery Management Systems (BMS):

- Sophisticated Charging Algorithms: The 315mA capabilities ensure optimal charge distribution across battery cells.

- Advanced Sleep Modes for Power Conservation: Enhances battery life and power efficiency in EVs and hybrid powertrains.

- Real-Time Monitoring & Fault Detection: Leverages low-dropout (LDO) regulators and high-efficiency DC-DC converters for stable voltage regulation.

3. ADAS & Autonomous Driving Power Requirements

- Multi-Rail Power Architecture: For sensor fusion systems, supporting LiDAR, radar, and vision-based computing units.

- Dedicated Compute Power Channels: For real-time image processing, ensuring low-latency ADAS performance.

- Redundant Power Paths with High Voltage MOSFET Protection: Safeguards safety-critical functions from unexpected power failures.

By integrating high-efficiency regulators, and intelligent fault monitoring, automotive-grade PMICs provide safe, scalable, and energy-efficient solutions for the future of connected, autonomous, and electric vehicles.

Integration of Advanced PMIC Technologies

Modern PMICs are transforming the semiconductor industry, offering enhanced power electronics solutions across various domains, from consumer electronics to industrial automation. These system-on-chip (SoC) solutions integrate transistors, diodes, and PWM controllers to regulate AC/DC power conversion, ensuring efficient voltage transformation with minimal energy loss.

Power Management IC used in Digital Micromirror Device Matrix

High-performance PMICs also incorporate power factor modulation (PFM) techniques to optimize switching regulators, reducing power dissipation in CPU-driven architectures. This optimization translates to improved energy efficiency and reduced thermal stress on components. Furthermore, careful PCB design plays a critical role in minimizing signal integrity issues and electromagnetic interference (EMI), ensuring stable power delivery across multiple domains. This is particularly important in noise-sensitive applications.

Advanced Ethernet-powered devices (PoE) leverage PMIC-based power regulation for efficient and reliable network connectivity, simplifying installation and reducing cabling costs. Meanwhile, continuous advancements in semiconductor foundry technologies are driving further improvements in the scalability, performance, and reliability of next-generation PMIC designs. These advancements include smaller feature sizes, higher integration levels, and improved power handling capabilities.

Whether in automotive, data centres, or embedded systems, PMICs remain central to transformer-based power supply designs, delivering high-efficiency power solutions with optimized energy management.

Design Challenges and Optimization

development of PMICs presents several design challenges, especially as electronic devices become smaller, more complex, and power-intensive. These challenges manifest across multiple domains, from thermal management to signal integrity:

| Challenge | Impact | Mitigation |

| Thermal Density | 35% Performance Loss | 35% Performance Loss |

| Signal Integrity | 20% Yield Impact | Impedance Matching |

| Power Noise | 15dB SNR Loss | Decoupling Strategies |

ActiveCiPS technology by Qorvo offers fully customizable PMIC solutions designed to overcome these challenges by:

- Maintaining compact form factors without compromising power efficiency.

- Enabling rapid configuration changes, making it ideal for mass-market applications where time-to-market is critical.

- Optimizing real-time power control, reducing thermal density and EMI interference.

To enhance power efficiency and system reliability, modern PMICs incorporate multi-rail power sequencing, which ensures:

- Proper system initialization by sequencing voltage domains in a controlled manner.

- Dynamic Voltage Scaling (DVS) to adjust power levels based on real-time system demands.

- Minimized inrush current, preventing power rail failures and component stress.

The NXP PCA9420 exemplifies advanced multi-rail power sequencing, offering:

- Programmable power states, enabling adaptive power management for low-power IoT, wearables, and industrial automation.

- Flexible rail sequencing, ensuring seamless transitions between power modes while maintaining voltage stability.

- Integrated Low-Dropout (LDO) and DC-DC Regulators, optimizing energy efficiency for battery-powered systems.

PMICs continue to drive advancements in next-generation electronic designs while addressing critical thermal, noise and signal integrity challenges.

Conclusion

Power Management Integrated Circuits are the unsung heroes of modern electronics, quietly ensuring that devices operate efficiently, safely, and reliably. From enabling ultra-efficient energy harvesting systems to powering advanced automotive applications, PMICs are at the heart of innovation across multiple industries. With the evolution in technology, PMICs will remain critical to addressing the challenges of power density, system complexity, and energy optimization. By pushing the boundaries of integration and efficiency, PMICs are paving the way for the next generation of electronic devices, transforming the way we interact with and rely on technology in our daily lives.